Powerful Crushing Solutions Await: Check Out the most up to date Impact Crusher for Sale

Powerful Crushing Solutions Await: Check Out the most up to date Impact Crusher for Sale

Blog Article

Revolutionize Your Recycling Procedures With an Effect Crusher

One such service that has actually gotten considerable interest is the impact crusher. Exactly how exactly does an effect crusher work, and what are the benefits it can provide? In this discussion, we will certainly explore the internal operations of an effect crusher, the kinds of materials it can process, and provide suggestions for maximizing its efficiency.

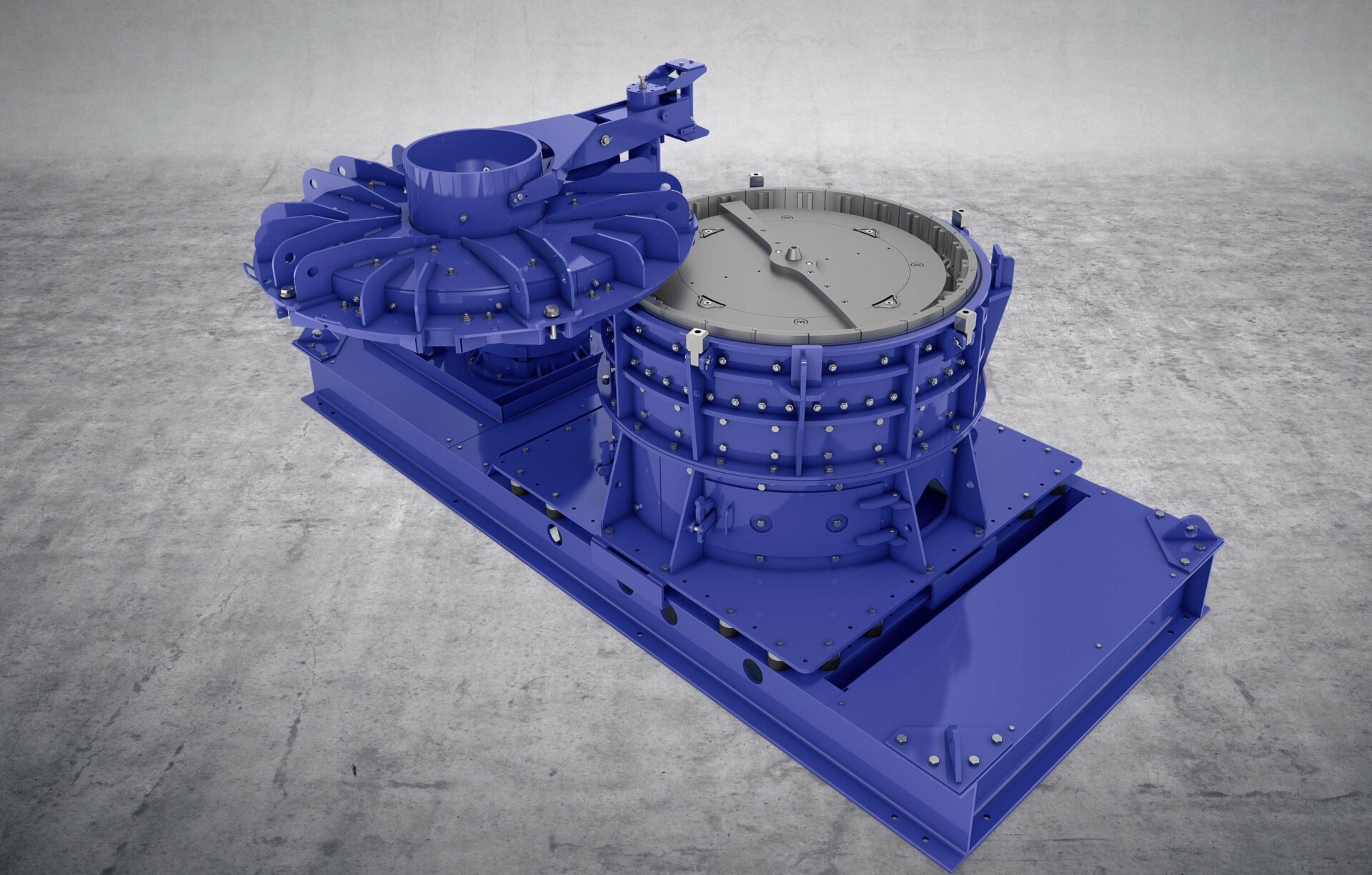

How an Effect Crusher Works

An influence crusher operates by utilizing a high-speed rotor and a crushing chamber to effectively damage down products right into smaller, much more workable dimensions. The fragmented product after that enters the crushing chamber, where it is more reduced in size by the effect forces created by the revolving rotor.

Among the crucial benefits of an effect crusher is its capacity to produce an uniform particle form. Unlike various other crushing approaches, such as jaw crushers, which tend to produce even more extended particles, impact crushers develop cubical-shaped fragments. This results from the high-speed effect forces created by the blades, which effectively shatter the product and create a much more regular item.

Moreover, influence crushers are highly functional machines that can deal with a wide variety of products. From soft and friable materials like limestone to hard and unpleasant products like granite, impact crushers can successfully refine various sorts of materials. This makes them ideal for use in recycling procedures, where different sorts of products require to be refined and transformed into recyclable products.

Benefits of Making Use Of an Effect Crusher

With its capability to produce an uniform fragment shape and deal with a vast variety of materials, the influence crusher supplies a wide variety of benefits in various reusing procedures. Among the crucial benefits is its effectiveness in reducing the size of products. The impact crusher uses a high-speed influence force to break down products, causing a much more cost-effective and efficient procedure contrasted to various other crushers. In addition, the impact crusher has a reduced operating expense as it needs much less upkeep and has a much longer life-span.

One more advantage of using an influence crusher is its adaptability. By generating regular bit sizes, the impact crusher makes sure that the recycled materials can be utilized for different purposes, such as roadway building and construction or as accumulation in brand-new concrete.

Kinds Of Products That Can Be Processed

The impact crusher is qualified of refining a broad variety of materials, making it highly flexible in recycling operations. One of the main products that can be refined by an influence crusher is concrete. The capacity to refine such a wide array of materials makes the impact crusher a necessary device in recycling procedures, making it possible for the healing and reuse of useful sources while lowering waste and environmental influence.

Tips for Optimizing Effectiveness With an Effect Crusher

To optimize the performance of an effect crusher and accomplish maximum efficiency, drivers must execute a number of essential approaches. Primarily, normal upkeep is necessary. This consists of routine examinations of the maker to determine any type of prospective concerns or damaged components that may influence its efficiency. Operators must also make certain that the effect crusher is properly lubricated to reduce rubbing and protect against unneeded wear and tear.

One more important tip is to readjust the crusher settings according to the details needs of the product being processed. This can be done by monitoring the feed dimension, the rate of the blades, and the gap in between the effect plates. By fine-tuning these setups, drivers can ensure that the crusher is operating at its ideal ability and producing the wanted outcome size.

Additionally, drivers must thoroughly pick the proper feed material for the effect crusher. This includes comprehending the characteristics of the product and its effect on the crusher's performance. It is vital to stay clear of feeding exceedingly tough or extra-large products that may cause damages to the device or cause ineffective squashing.

Finally, operators must on a regular basis check the performance of the impact crusher and make changes as needed. This can be done by evaluating the item high quality, manufacturing rate, and energy usage. By continuously optimizing the crusher and assessing's efficiency, operators can take full advantage of efficiency and lower downtime.

Ecological Effect of Using an Effect Crusher

Routinely checking and optimizing the performance of an influence crusher not just maximizes efficiency and lowers downtime, but it likewise enables drivers to assess and alleviate the ecological effect of using the find out this here crusher. The ecological influence of utilizing an influence crusher can be considerable, especially if appropriate procedures are not required to minimize it. One of the major issues is the exhaust of dirt and particle matter during the page squashing procedure. These fragments can add to air pollution and can have harmful effects on human health and the bordering ecological community.

To reduce this effect, drivers can implement numerous procedures. Additionally, normal upkeep and examination of the crusher can assist determine and deal with any type of concerns that may lead to enhanced dirt emissions.

An additional environmental issue is the sound created by the influence crusher. They can also set up squashing operations throughout times when sound impact is minimized, such as during daytime hours when noise from surrounding tasks is higher.

Verdict

To conclude, integrating an influence crusher into recycling operations can change the procedure by properly enhancing and crushing numerous materials performance. The advantages of using an impact crusher consist of reduced waste quantities, increased manufacturing rates, and boosted product high quality. By following pointers for making best use of effectiveness and considering the environmental influence, recycling procedures can greatly benefit from using an influence crusher.

The impact crusher uses a high-speed influence force to break down products, resulting in a more cost-effective and efficient process contrasted to various other crushers. The capability to refine such a wide array of products makes the effect crusher a vital device in recycling procedures, enabling the healing and reuse of beneficial resources while decreasing waste and environmental impact.

On a regular basis monitoring and maximizing straight from the source the efficiency of an effect crusher not only maximizes efficiency and minimizes downtime, but it likewise allows operators to analyze and mitigate the ecological effect of utilizing the crusher. The environmental effect of using an impact crusher can be significant, particularly if correct actions are not taken to reduce it. By adhering to tips for maximizing efficiency and thinking about the environmental effect, reusing procedures can considerably benefit from the use of an influence crusher.

Report this page